Boiler Appearance Picture

Boiler Structure Introduction

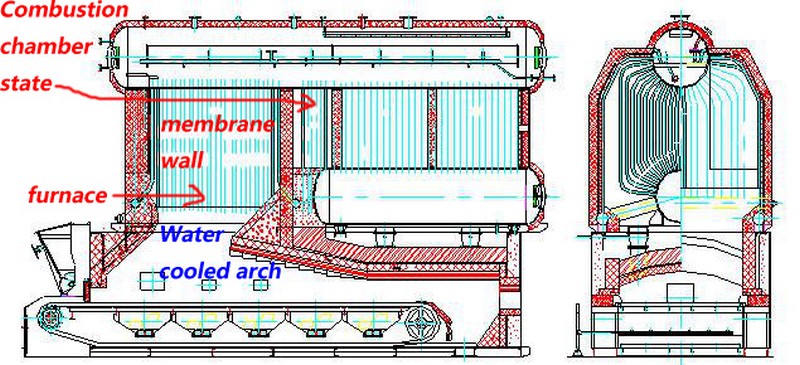

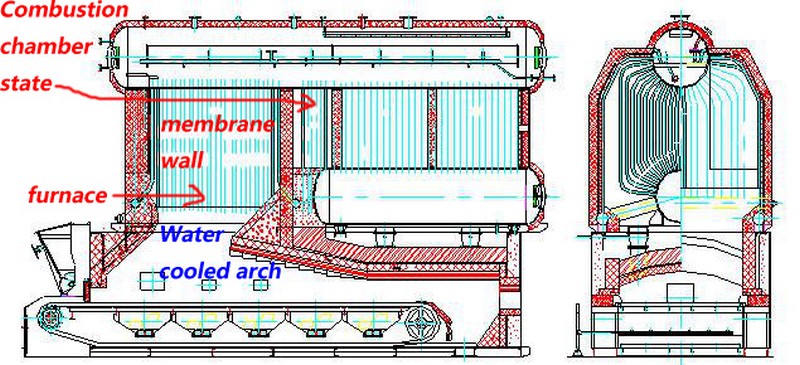

The Internal Structure

Chain Grate Stoker

Product structure features

1.SZL series shop-assemble water tubes boiler, which is a vertical type with double drums, uses chain grate as its combustion mode with rated evaporative capacity: 4-20t/h. this boiler uses Class II bituminous coal, the two sides of whose furnace adopt membrane water-cooled wall structure. The tubes of water-cooled wall go down to the up side of the furnace which forms the front and rear arches so that the seal structure and intensity of back arch are enhanced and the cubic of the furnace and heating surface are enlarged. There are end combustion chamber and convection tube tank in the back of the furnace with fixing an economizer in the rear. After through the furnace, end combustion chamber, convection tube tank and economizer, the flue gas came into the flue duct in the rear, and then went by dust precipitator, induced draft fan &chimney, and was discharged into the air in the end.

2.This boiler is divided into two parts the upper part and the lower part before leaving the factory. The upper part involves boiler proper, steelwork and upper boiler setting, while the lower part involves coal hopper, chain grate, lower boiler setting and internal ventilating duct. Except site-assembled tubes of front & rear arches including its connection tubes and site-built part of the boiler setting with front & rear arches, the rests are packaged for duty with its economizer in the tail part and flue duct before leaving the factory, while the dust precipitator in the tail part and its connection tubes would be delivered according to the contract.

3.Combustion system:Combustion system involves coal hopper, chain grater and transmission device.

This boiler adopts mass fire grate flakes. And the wind is fed from both sides of the boiler by several independent air chambers below the grate to make flow uniform overall, which could be adjusted in accordance with the burning condition. The feeder hopper and valves are installed in the front part of the furnace to regulate the thickness of the materials on the grate, whose speed is controlled by reduction box. Finally, after combustion, the slag will be discharged into the slag hopper.

Product technical features:

SZL series water-cooled arch and membrane water wall assembly boiler is a new type of water pipe assembly boiler. It applies the water-cooled arch technology and membrane water wall technology of large chain grate boiler combustion system to the assembled boiler. The technical indicators are at the domestic leading level.

1. Membrane water wall structure is adopted on both sides of the furnace and the combustion chamber. The membrane water wall structure is an independent and unique design of our company. The membrane water wall structure used for power station boilers is applied to the assembled boiler. The advantages are good heat transfer effect, low heat loss, good air tightness and no deformation of the furnace wall. Not leaking.

2. Before and after the furnace, the water wall tube extends downward to the upper part of the grate to form the front and rear arches. The structure is added on the basis of the original mature bulk boiler. On the basis of other heat-receiving areas, the furnace radiation heating surface is added, and the overload capacity is stronger. The front and rear arches are made of water-cooled wall pipe and cast with high-aluminum cement. Therefore, the disadvantages of cracking and arching of the long-term high-temperature barbecue of the original boiler tri-fold line arch brick are avoided, thereby prolonging the service life of the arch.

3. The inverted “α” furnace arch technology used in the furnace arch, the front arch is high and short, the rear arch is low and long, which increases the burning time of the flue gas in the furnace and improves the combustion efficiency; the streamlined rear arch can be used for the grate The unburned carbon particles blown up in the middle and rear part are thrown to the front, making the coal more flammable, and the fire line is neat; the fuel has wide adaptability.

English

English